MEMBER PROFILE

NAKASA Co. Ltd.

113-15 Enoshimacho, Yasugi, Shimane Prefecture, 692-0057

TEL:+81-854-23-0873 / FAX:+81-854-23-1433

URL:http://www.nakasa.co.jp

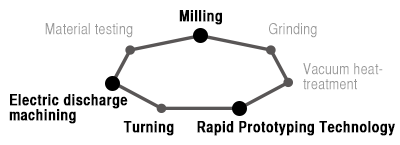

Position of technology in SUSANOO

Come to SUSANOO for machining of near net shape molded products including lost-wax and MIM.

We are a NC machining manufacturer, specializing in large scale mass production processing.

We provide an integrated response from support in the development stage until final mass

production.

STRONG POINT

We meet our customer's demands with the finest service available.

We are an NC machining manufacturer, specializing in large scale production processing.

We provide an integrated response from support in the development stage until final mass production.

Technical Strengths

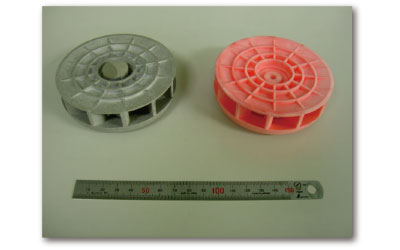

■Significantly reduce development time with moldless precision casting prototyping

Rapid prototyping system using SLS method.

Laminating powder by sintering and melting with laser. Utilizing it as

evaporative pattern in lost wax casting method facilitates much shorter production lead time.

We have 10 years of experience in manufacturing using 3D printers.

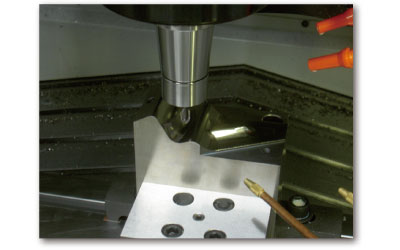

■3D processing of high hardness materials and difficult-to-cut materials

We also process 3D shapes of 60HRC high hardness material parts.

■Lathe-turning of heat-resistant steel

We have over 20 years of rich experience in processing cobalt and nickel

heat-resistant alloys.

■Using wire cut electrical discharge machining from mold machining to

mass production machining

We are capable of machining work pieces of thickness up to 400mm.

■CAD/CAM

We have over 20 years experience in 3D manufacturing with CAD/CAM.

A lost wax model made by 3D printer and a casting

Progressive press mold (SKD11) Machining of high hardness 60HRC parts

■Our process example

Inconel cut parts

Progressive Press Mold / SKD11

■Materials to work on

Stainless steel, alloy tool steel, high-speed tool steel, alloy steels for machine structural use, carbon tool steel, heat-resistant cast steel, Ni-based superalloy, Co-based superalloy, Kovar

■Certifications

ISO 9001

JIS Q 9100

■Our Industrial fields

Automotive, industrial machinery

■Main Equipment

| Equipment | QTY | Dimensions etc. |

|---|---|---|

| Powder Layering Fabrication Equipment | 1 | 3Dsystems |

| Vertical Machining Center | 22 | Mori Seiki and other |

| Horizontal Machining Center | 2 | Makino and other |

| High-speed Machining Center | 1 | Makino |

| CNC Lathe | 14 | Mori Seiki and other |

| Turning Center | 2 | Mori Seiki and other |

| Wire cut electrical discharge machine | 4 | Makino and other |

| Die-sinking electrical discharge machine | 1 | Mitsubishi Electric Corporation |

NC Lathe

Vertical Machining Center

Powder Layering Fabrication Equipment