MEMBER PROFILE

Hadaseikou Co., Ltd.

691 Kuroidacho, Yasugi, Shimane Prefecture, 692-0023

TEL:+81-854-22-3774 / FAX:+81-854-23-0079

URL:https://www.hadaseikou.co.jp/

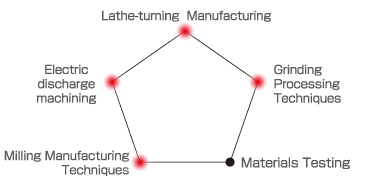

Position of technology in SUSANOO

We accept integrated orders for thin lathe-turned products, from material procurement to the finished product.

• Lathe-turning up to φ2,000mm

• Composite grinding up to φ1,200mm

• Installation of 15 tons cranes

STRONG POINT

We accept integrated orders for thin lathe-turned products, from material procurement to the finished product.

Lathe-turning up to φ2,000mm

Composite grinding up to φ1,200mm

Installation of 15 tons cranes

Technical Strengths

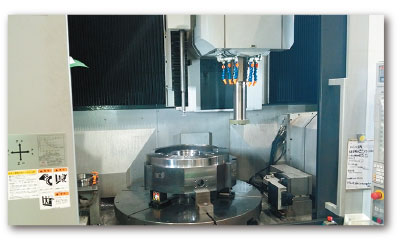

■High-precision lathing of ring-shaped parts

Semi-finishing of super heat resistant alloys and titanium alloys, high precision lathing

of half-split shape large, medium, and small thin rings. Our NC vertical lathe can suppress

deformation of thin rings after processing by fixing the part in place from above.

■Heavy cutting of difficult-to-cut materials

HADASEIKOU CO., LTD. facilities have high-output specification spindle motors, so we

are capable of heavy cutting of items weighing up to 15 tons and difficult-to-cut materials.

■Composite Grinding

High precision composite grinding with Taiyo Koki Vertical Mate 125.

It is capable of grinding the inner diameter, outer diameter and end face in a single step

with the same precision as conventional devices. Its vertical set up is effective for high

roundness grinding of thin rings. Also capable of high precision grinding of the concentricity

of inner and outer diameters, and squareness of end face and inner and outer diameters.

■Design and manufacture of various types of jigs and tools

We can design and manufacture of various types of jigs and tools tailored to the

required accuracy, from small parts to big parts of up to 2m.

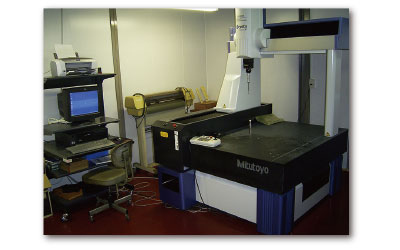

■Quality Management

We guarantee the quality by JIS Q 9100 certification, coordinate measuring machine,

image measuring instruments, ultrasonic inspection and penetrant inspection.

Large vertical lathe

Composite Grinding

Quality Management

■Our process example

High hardness parts

Half-split parts

■Available Materials

We specialize in super heat resistant alloys (Inconel, Hastelloy, etc.), titanium alloys, various stainless steels, and high hardness tool steel.

We also support copper alloys and aluminum alloys

■Achievement in aerospace industry

Primary material lathing of turbine disk cases, holder cases, flanges, bearing cases, and titanium shafts

■Certifications

JISQ9100, MSJ4000

■Our Industrial fields

Aircraft-related, energy-related, large industrial machine parts such as large compressors, and automotive parts

■Main Equipment

| Equipment | QTY | Dimensions etc. |

|---|---|---|

| NC Vertical Lathe | 10 | VTLex 2000 OM φ2000×1800mm high-pressure coolant 7MPa VTLex 915 OM φ915×800mm |

| NC Lathe | 16 | SL403C / 2000 Mori Seiki φ600 × 2000mm LB3000EX Okuma φ400×1000mm |

| NC Composite lathe | 1 | NLX2000 Mori Seiki φ150×400mm |

| 5 Face Machining Machine | 1 | MVR30Ex Mitsubishi Heavy Industries X2000 Y3000 Z1500mm |

| Machining Center | 2 | MB-56VB Okuma X1050 Y560 Z460mm |

| Centerless Grinder | 3 | MPC-600Ⅲ micron precision φ20, 300mm or lower, others |

| Composite Grinder | 1 | Vertical Mate125 Taiyo Koki Hole diameter: φ50~1200mm, Outer diameter: up to φ1200mm Length: 500mm |

| Wire-cut Electrical Discharge Machine | 4 | FA-20 Mitsubishi Electric X350 Y500 Z300mm |

| Sinker Electrical Discharge Machine | 3 | EA12V Mitsubishi Electric X700 Y500 Z300mm |

| Coordinate measuring machine | 2 | CRYSTA-Apex 1600 X1600×Y3000×Z1000mm |

VTLex 915 OM

Virtical Mate125