MEMBER PROFILE

MAKATA INDUSTRY INC

786 Yawatacho, Matsue, Shimane Prefecture 690-0025

TEL:+81-852-37-0106 / FAX:+81-852-37-0107

URL:https://makatakg.com/

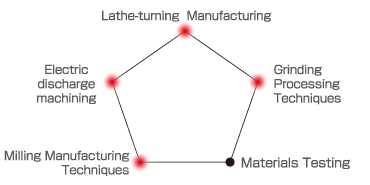

Position of technology in SUSANOO

Our expertise is in machining heavy gauge and long length specialty steel products.

We also offer combined machining.

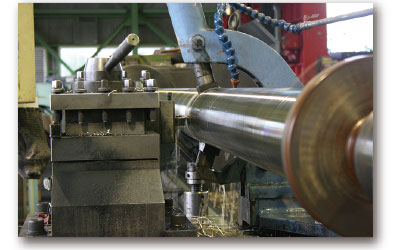

We primarily perform machining (cutting and lathe turning) on as-forged specialty steel material.

We are capable of machining medium-sized (φ100 - φ1000) rings and disks as well as (φ50 - φ500 × 8000L)

round bars with our horizontal lathes.

STRONG POINT

Our expertise is in machining heavy gauge and long length specialty steel products.

We also try machining on contoured cylindrical material.

We primarily perform machining (cutting and lathe turning) on as-forged specialty steel material.

We are currently aiming to increase our technical capability with the

introduction of multi-axis machines, and will try machining on 3D contoured cylindrical parts.

Technical Strengths

■Rough lathe turning on as-forged super heat resistant alloy materials

Long parts: Capable of lathe-turning of long parts with general-purpose lathe of 8000mm between cores(Actual maximum φ230×7260mm)

Disk Ring Parts : Standard request tolerance ±0.5mm

■Rough lathe-turning of stainless steel long products

7000L φ160±0.5mm full-length swing≦1.0mm

Rough lathe-turning of super heat resistant alloy forging materials

Rough lathe-turning of stainless steel long parts

■Large saw cutting of difficult-to-cut materials

Capable of sawing large difficult-to-cut materials with Japan's largest band saw

1000×1000mm thin slice 10.0±0.5mm

■Long anti-vibration bar

φ100mm cemented carbide long anti-vibration bar(Sandvik)

Maximum machining length: 1500mm, Minimum machining diameter: φ120mm

Sawing of difficult-to-cut materials

Long anti-vibration bar

■Our process example

NC Lathe-turning

Saw cutting

Machining Centers

General purpose lathe-turning

■Available Materials

Heat-resistant steel, super heat resistant alloys,titanium alloy, stainless steel, tool steel,etc.

■Achievement in aerospace industry

Low-pressure turbine disks, shaft

■Certifications

JISQ9100

■Our Industrial fields

Aerospace, gas turbine, nuclear, electronic devices, etc.

■Main Equipment

| Equipment | QTY | Dimensions etc. |

|---|---|---|

| General-purpose lathe | 18 | Dainichi Kinzoku DL95×800 Bed 980 Between Cores 8000 |

| NC lathe | 10 | Dainichi Kinzoku M152×200 Bed 1520 Between Cores 2000 |

| Composite lathe | 3 | Yamazaki Mazak integrex e670H Centre-to-centre 6000 |

| Saw | 13 | AMADA H-2116 width 2100mm height 1600mm |

| Machining Center | 2 | Okuma MCV-AⅡ X2000×Y1600×Z450mm |

| Rotary Grinder | 4 | Sumiju Fine Tech SVR18A Electromagnetic chuck diameter 1910mm maximum processing height 640mm |

| Underwater wire cut electric discharge machine | 2 | Makino Milling U86 X800×Y600×Z320/500mm |

| 3D Coordinate Measuring Device | 1 | Tokyo Seimitsu ACCURA X1200×Y4200×Z1000mm |

| 5 Axis Machining Center | 1 | Yamazaki Mazak VARIAXIS i-1050T chuckφ1250 |

| Vertical CNC lathe | 1 | Yamazaki Mazak MEGATURN1600M chuckφ1500 |

Yamazaki Mazak Integrex e500HⅡ

Mori Seiki LL-8

Mori Seiki SL603

Long General-Purpose Lathe